Our Approach to Quality Control

Inspections, also known as Routine Tests, are the most crucial stage during the whole production process. Only an effective Inspection Plan will ensure all of the products to have the best quality in the market. There are three different types of Inspections involved, Incoming, In Process and Outgoing. At every stage, the according inspections will be done by experienced Inspectors and monitored by Qualified Officers.

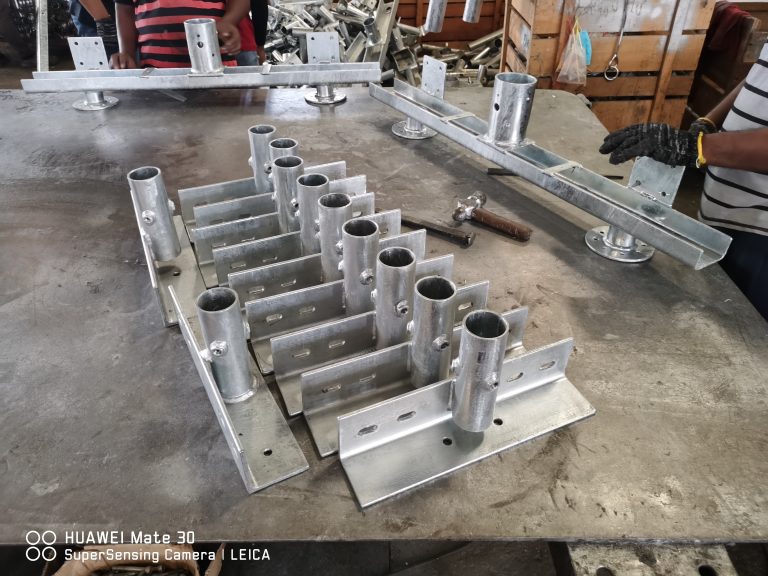

Inspections of our product are further divided to several categories: